Do you do TRUSS WORK / TRUSS FABRICATION.?

YES, We do Truss Work at a very reasonable cost from Just Rs 500/sft onwards.

COST OF TRUSS WORK.?

The cost of Truss work in Bangalore starts from Rs 500/sq ft for a terrace balcony with 10ft height clearance with lightweight supports.

The cost for truss fabrication increases or decreases based on the designs given by the appointed Architects at Bangalore or Hired Structural consultants to work on the project; the cost increases if the height and span of the building will increase.

In this case, the “ I Sections ” or Columns used will be of heavy gauge due to the internal span of the structure. In this case, one can consider Rs 1100/sq ft excluding civil works.

WHAT BUILDINGS REQUIRE TRUSS WORK/TRUSS CONTRACTORS SERVICES.?

If one needs to BUILD a Large building without any internal obstacles/visible columns, which might affect the movement of internal traffic.

In such cases, TRUSS WORK fabrication is required; some of the Buildings that might require are Industrial sheds, Marriage halls, Cold storages, Auditorium, Terrace structure, Warehouses, Gowdons, Factories, Godowns, Covering Balconies, Temporary structures, Stage covering for events, Roof work, Industrial buildings, Large conference halls, Cinema halls, Cafeteria, etc.

Useful details: Current Residential construction cost | Rates of Building Contractors | House Construction

Contents

SAMPLE TRUSS FABRICATION / TRUSS WORK COST IN BANGALORE with DESIGN

Below are the below-given details: a SAMPLE rough Truss Fabrication cost in Bangalore for a 200×300 or 60,000 sq ft building along with the required civil work like Masonry work, Brickwork, Plaster Rolling shutters, Painting, Waterproofing, Washrooms, Cement flooring, Openings, etc.

PROPOSAL: BUILDING of 200 x 300 or 60,000 sq ft

ESTIMATE FOR STRUCTURAL STEEL FABRICATION for the ABOVE TRUSS DESIGN:

| Sl no | TRUSS WORK IN BANGALORE COST DESCRIPTION | QUANTITY | UNITS | RATES | AMOUNT |

| SECTION – 1 EARTHWORK | |||||

| 1.1 | Earth work excavation by manual means over areas including disposal of excavated earth up to lead of 200m or very close to the site for refilling, the disposed earth to be leveled and neatly dressed and stacked.

i) All types of soil. |

419.37 | Cum | 250 | 104841.45 |

| 1.2 | Supplying and filling in plinth with good earth brought from outside for filling under floors including, watering, ramming power rolling, consolidating and dressing completely. | 5860.70 | Cum | 380 | 2227066.82 |

| 1.3 | Filling the basement/sides of foundation trenches with excavated earth/boulders, including watering ramming and consolidation, etc., complete. | 390.31 | Cum | 150 | 58545.97 |

| SECTION – 2 PLAIN CEMENT CONCRETE WORKS: PCC |

|||||

| 2.1 | Providing and laying cement concrete in position cement concrete of specified grade excluding the cost of centering and shuttering – All work up to plinth level (a) 1:4:8 (1 cement: 4 sand: 8 graded stone aggregate 40 mm nominal size), for foundation and floor base. | 683.75 | Cum | 3800 | 2598244.62 |

| SECTION – 3 REINFORCED CEMENT CONCRETE WORKS |

|||||

| 3.1 | Providing and laying in position machine batched mixed and vibrated design mix cement concrete of specified grade for reinforced cement concrete structural elements excluding the cost of centering, shuttering, finishing. Reinforcement M – 20 grade reinforced cement concrete. (Cement content shall be taken as 340 Kg/cum of concrete). a) All works upto the plinth level. (o.om lvl) |

156.37 | Cum | 5250 | 820925.64 |

| 3.2 | Centering and shuttering, including strutting, propping, etc., and removal of form for: a) Foundations, Footings, bases of columns, etc., for mass concrete. c) Lintel, beams, plinth beam, griders, bressummers, and cantilevers. d) columns, pillars, piers, Abutment, post, and struts. |

2052.04 | Sqm | 400 | 820817.84 |

| 3.3 | Reinforcement for R.C.C. work, including straightening cutting, placing in position, and binding, all complete. (quoted price = basic steel supply price + labor + overheads). | 16808.75 | Kg | 75 | 1260656.25 |

| SECTION – 4 TRUSS MASONRY WORKS |

|||||

| 4.1 | Brickwork with clay fly, ash F.P.S brick of class designation from plinth level to ground floor: a,) cement mortar 1:6 (1 cement: 6-course sand). | 641.26 | Cum | 3950 | 2532992.57 |

| SECTION – 5 WALL FINISHING | |||||

| 5.1 | Internal & External cement plaster on the rough side or half brick wall / full brick wall (fly ash) of mix a)1:6 (1 cement:6 coarse sand) | 2137.55 | Sqm | 350 | 748141.26 |

| 5.2 | Preparing and applying two coats of approved quality, make and shade of waterproof CEMENT PAINT (snowcem/surfacem or equivalent) over a coat of primer at all levels including necessary scaffolding, curing, etc., complete Outer surfaces. | 2137.55 | Sqm | 42 | 89776.95 |

| SECTION – 6 FLOORING WORK |

|||||

| 6.1 | Reinforced concrete floor finishing in all areas using M25 concrete with 20mm HBGSJ, 7% micro silica by weight of cement, using water at a water-cement ratio of 0.4, including power towelling and floating (dewatering shall be avoided). Groove cutting shall be made at grids of approximate filling the grooves with polysulphide sealants etc., complete. | 6412.64 | Sqm | 980 | 6284386.62 |

| TOTAL CIVIL WORK COST | COST | Rs | 17546400.00 | ||

| SECTION – 7 TRUSS FABRICATION / STRUCTURAL STEEL WORK | |||||

| 7.1 | Supply, Structural Steel fabrication & erection of PEB Structural Members. | 250.00 | Ton | 95000 | 23750000.00 |

| 7.2 | 30mm Roof Panel. | 5580.00 | Sqm | 1600 | 8928000.00 |

| 7.3 | 80mm Wall Panel | 3160.00 | Sqm | 2580 | 8152800.00 |

| 7.4 | All flashings, Trims & Accessories | 370.00 | Rm | 900 | 333000.00 |

| 7.5 | Rolling Shutter (5m x 3m) 6 Nos | 90 | Sqm | 2690 | 242100.00 |

| 7.6 | Truss Canopy 6 nos (5mx3m) | 90 | Sqm | 1450 | 130500.00 |

| TOTAL STRUCTURAL AMOUNT | COST | Rs | 41536400.00 | ||

| TOTAL TUSS WORK COST INCLUDING CIVIL WORK AND TRUSS FABRICATION WORK.

GRAND TOTAL : 5,90,82,800.00 |

TOTAL | Rs | 59082800.00 |

Terms and Conditions:

VAT & Service Tax : VAT shall be charged @ 5% for the material value ( 70% of total value ) & Service Tax shall be charged @ 15% for the labor component.

Payment Terms:

- 30% Advance along with the Purchase order.

- 60% Running Bill Based.

- 10% After Full completion.

- Completion of work within 60 days from the Date of Advance (depends on advance).

- Final billing As per Actual Measurement and Weight.

- The validity of the Proposal will be for 15 days.

.

TRUSS WORK IN BANGALORE.?

What is a Truss?

A truss is a framework that typically supports a roof or bridge or any other structure and consists of rafters, struts, and posts. There will be two force members, and the members will be organized to appear like a single unit.

If you go through two force members, the force will be applied at two points only. The two members can be connected in any shape to achieve a stable configuration. If you go through a truss, there will be 5 or more triangular units. The units are constructed with straight members, and the ends are connected at joints (nodes).

What are Truss Forms?

– The bridge is nothing but the assemblage of several sections. These sections are joined at various angles, including horizontal, vertical, and inclined shapes. The sections are termed, truss members.

– The truss members will distribute the load to keep the structure in a stable condition. The members are assembled systematically. There are various kinds of trusses.

– As per the workspace, there are two trusses. They are planar truss and space truss. In a planar truss, members lie in a two-dimensional plane, and in a space truss, members lie in three dimensions.

– There are three components in a truss. The top chord is the beam which will be in compression, and the bottom chord will be in tension. Webs are middle beams.

– One can order trusses as per the requirement of span length and loading condition. They are mentioned as bridge trusses and roof trusses.

What are the Advantages of having Trusses?

– A truss can be told as a building invention that facilitates the distribution of load of the roof through the outer walls in a very efficient way. The truss shape will be triangular. It is made up of multiple triangles as well. The triangular shape will give more support to the building, and it is possible to complete construction with fewer building materials.

– You can install a truss very quickly. Thus, you can manage temporary constructions and permanent constructions in the shortest possible time without any issues. Most of the trusses are made in factories, and they will be delivered to the job site as a complete set. In this manner, the structure can be constructed very quickly.

– The truss will be leveraged at the top of the wall. It will be slid and pivoted before fastening in its place. Trusses can span longer distances. The triangular roof can withstand shift and sag in a very efficient manner. The set of trusses will be stable, and they can withstand weight many times the weight of a straight roof.

– Trusses are meant for efficient load distribution. The weight applies on the sides will be redistributed down. The interior walls can be built arbitrarily or can be moved as per your needs. The triangular spaces present in trusses can be used to carry the HVAC cables and electrical wires. Roof trusses offer great flexibility in the plan layout. Timber roof trusses are popular in the USA, Canada, and other countries.

Info: G+2 G+3 G+1 Building cost | Getting Residential House plans

Why do we need Truss Work?

Truss work is used in the construction of roofs and bridges. You can prepare an efficient structural form by planning with the depth of the truss. The depth is nothing but the height between the upper and the lower chords. The truss is a lightweight structure. If you go for a solid structure in place of a truss, you will incur great expenditure as the material cost will be very high.

Why is a truss different!

– Trusses are different from other kinds of structures. A truss will give you the advantage of transferring the load from one location to another location as per your needs. You can avoid load at the unwanted position by transferring or distributing the load through the framework.

– The roof truss bears the weight of the roof. Suppose you live in a geographical location where heavy snowfalls on the roof can transfer the weights to the walls in a very efficient manner. In this process, structural stability will be maintained.

– If you go for a bridge truss, the weight of vehicles (cars and trucks) will be transferred to piers. Trusses will take advantage of the geometry, and the laws of statics are involved in transferring the weight.

WHY do we need TRUSS Work?

One can prepare an efficient Truss work by structural steel fabrication in Bangalore by planning with the depth of the truss. The depth is nothing but the height between the upper and the lower chords. The truss is a lightweight structure. If you go for a solid structure in place of a truss, you will incur great expenditure as the material cost will be very high.

Why is a truss different?

– Trusses are different from other kinds of structures. A truss will give you the advantage of transferring the load from one location to another location as per your needs. You can avoid load at an unwanted position by transferring or distributing the load through the framework.

– The roof truss bears the weight of the roof. Suppose you live in a geographical location where heavy snowfalls on the roof can transfer the weights to the walls in a very efficient manner. In this process, structural stability will be maintained.

– If you go for a bridge truss, the weight of vehicles (cars and trucks) will be transferred to piers. Trusses will take advantage of the geometry, and the laws of statics are involved in transferring the weight.

Different Shapes of trusses for Truss Fabrication Work?

TRIANGULAR

If you go for a triangular structure, the rigidity of the structure is not based on the connections. Thus, you can prepare a structure with some triangles, and a truss will be formed in a very efficient manner.

RAFTERS

There is a difference between rafters and roof trusses. If you use roof trusses in the construction of a building, the roof’s load-bearing capacity will be very high. There are certain advantages and disadvantages associated with roof trusses. Most of the traditional homes were built with wooden rafters. Traditional lumber was used to give support to the roof.

The rafters are tied to the board at the top, and it is called the ridge board. The horizontal members are called collar ties. Collar ties play an important role in holding the rafters and roof planes. Beams are meant for small and open designs. You will be able to construct rafters without going through drawings.

DESIGN as per Requirement!

As great planning is required before the execution of Structural steel fabrication by Truss Contractors in Bangalore for roof trusses, One needs to think. If you are executing a complicated project, you should want to spend time planning and implementing.

It is possible to build a garage by using rafters. However, roof trusses are meant to last a lifetime. When you design a project with accurate drawings, the roof truss will serve your need in a very efficient way.

Selecting the Right Truss Fabricator

There will not be a major difference between rafter and roof truss in terms of quality. The cost factor plays an important role in the selection of rafter. The delivery cost of the raw material, erection cost, and the cost incurred in handling the job should be calculated. One should approach professional Truss Fabricators to help you choose the best structure to fulfill your needs.

Other details: Plan sanction | Procedure of Building a House | Procedure for BESCOM Connection

TRUSS FABRICATION IN BANGALORE

Roof trusses are used in-house and commercial construction of buildings based on Truss Work like Industrial Sheds, Large conference halls, Cafeteria, Temporary structures, Garage, Covering Balconies, Warehouses, Roof work, Cold Storage, Industrial buildings, Gowdons, Stage covering for events, Marriage halls, Terrace structure, Cinema Halls, Auditorium, Factories, etc.

The Truss roofs in Bangalore are designed for load carrying with Roof trusses that will be very efficient. If you go for T-bracing and roof sheathing, the strength will be very much enhanced.

There are different members in a truss. Each member will perform the task in a very efficient manner. You should understand the loads and the loading mechanism to settle for the right kind of truss design. Truss work is implemented in the design of various kinds of buildings.

As Truss Work contractors in Bangalore, we do Truss Design, Truss Fabrication, Roof trusses, Truss work design, Turnkey truss work, Heavy roofing trusses, Terrace Truss work or Fabrication for Cold storages, Schools, Apartments, Industrial sheds, Godowns, Warehouses, Commercial buildings, Flats, Sports complex, Badminton court Truss complex, Factories at the below locations.

Locations: Sarjapur Road, Kanakapura Road, Hosur Road, Devanahalli, Tumkur road, Bellary road, Doddaballapur road International airport road, Gowribidanur, Mastenahalli, Yelahanka, Whitefield, Yeshwantpur, KR Puram, Kannahalli, Ramchandrapuram, Magadi Road, Chandapura, Nelamangala, Dasanapura, Harohalli, Bannerghatta road.

BANGALORE URBAN:

Bommasandra, Attibele, Kachanayakanahalli, Bommasandra IV Phase, Kadugodi-Sadaramangala, Kumbalagudu, Bommasandra-Jigani Link Road, Dyavasandra I II Phase, Doddanekkundi I II Phase, Electronic City, EOIZ, EPIP, Peenya, Veerasandra.

BANGALORE RURAL:

Doddaballapura, Dobaspet, Hoskote, Dobaspet II Phase, Obhadenahally, Bengaluru Aerospace -SEZ, D.B.Pura Apparel Park I Phase, Dobaspet II Phase, Avverahalli (Dobaspet IV Phase), Sompura I & II Phases.

INDUSTRIAL AREAS:

Peenya industrial area, Jigani Industrial Area, Kumbalgudu Industrial Area, Dabaspete ( Bengaluru-tumakuru road ), Dabaspete ( bengaluru-tumakuru road ), SSI Industrial Area, Rajaji Nagar, DDK Industrial Area, 1st Phase, ITPL Road, Petechannappa Industrial Area, Kamakshipalya, Magadi Main Road, Bengaluru, Kiadb, Industrial Area, Hosur Road, Neelasandra, Dobbaspet, Nelamangala, Bidadi Industrial Area, Dyvasandra Industrial Area, Bommasandra Industrial area, Maluru Industrial area, Ekarajapura industrial area, Ramanagara Industrial Area, Narasapura industrial area, Jakkasandra Industrial Area, Vemgal Industrial Area, Mastenahalli Industrial Area,

Other Locations of Karnataka:

Mandya, Mysore, Tumkur, Dharwad, Koppal, Chitradurga, Chikkaballapur, Bijapur, Dakshina Kannada, Bagalkot, Chamarajanagar, Davanagere, Kolar, Belgaum, Gadag, Hassan, Bengaluru Urban, Bengaluru Rural, Chickmagaluru, Kodagu, Kalaburagi, Bidar,

What Types of Buildings require Truss Work/Truss Fabrication and WHY?

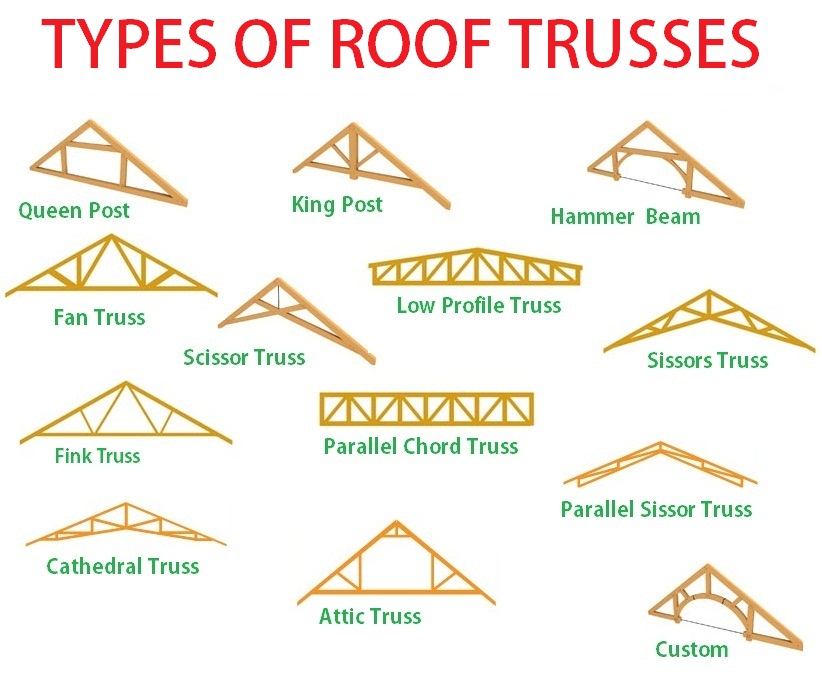

Various types of roof trusses

There are various types of roof trusses. Woodroof trusses are common. You will find various kinds of trusses designed to give firm support and distribute the load in a very efficient manner. Trusses are built by using various kinds of materials to make the most of your money.

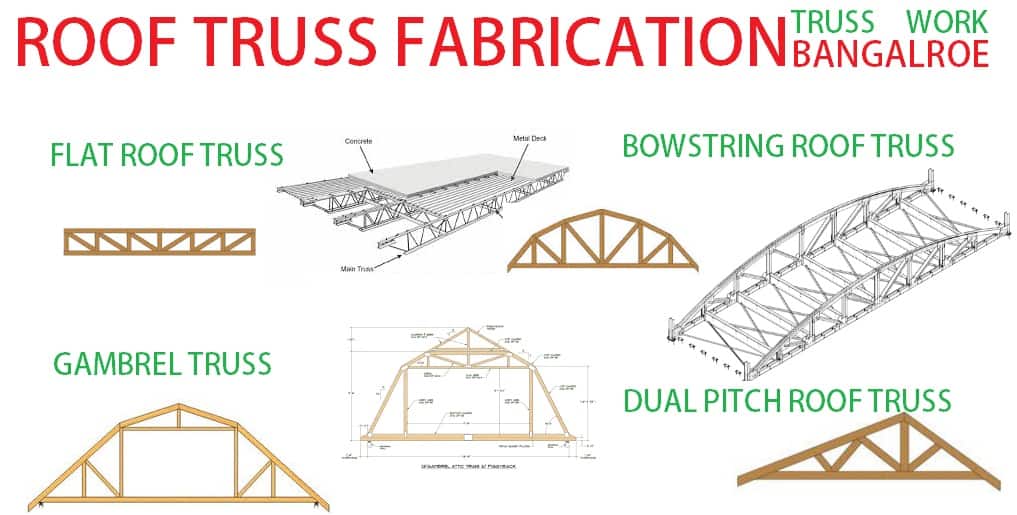

FLAT TRUSSES

As you go for a flat truss, there will be a top or bottom chord bearing. The load will be distributed through multiple simple spans. A flat truss will have a cantilever at one or both ends.

You can prevent water pooling by going for the inclined truss. If you go for an inclined roof, the damage to the structure can be prevented. There will be great stress on webs of flat trusses. Hence, this kind of Roof truss is considered the most inefficient truss.

GAMBREL TRUSSES

The truss will appear like a barn roof. There will be two upper chords, and one chord will be longer than another chord. The two chords will meet at the truss’s apex. There will be sufficient space for living as the truss comes with steep sides.

You can use the space for storage as well. The gambrel truss can be implemented at home so that the upper portion beneath the roof can be used as a second floor. You can provide a staircase to the upper floor. You can go for large windows so that the illumination will be good.

BOWSTRING ROOF TRUSS

Bowstring roof trusses are huge, and they are present in the arch form. They will give great support to the building by distributing the weight in a very efficient manner. Warehouses can be constructed by using the bowstring roof truss. You can manage large aircraft hangers as well by choosing the right design.

Several beams are used to make the arch. The outside roof is made of a metal sheet. You can use any other strong material also as per your requirements. You will not want to place a ridge cap in this construction, and the water will flow from the roof very efficiently.

DUAL PITCHED TRUSSES

Dual pitched trusses are nothing but the triangular truss design. The two sides will slope up to the apex on the top, and the struts (upper chords) will come down from it.

The struts will be attached to the horizontal beam, making up the triangle’s base. The upper chords are made of different lengths. Thus, the apex will be off-center. You can manage a lot of open space in this construction as the poles will not obstruct space.

ROOF TRUSS FOR A GARAGE

Roof trusses can be used in the construction of a garage. You can approach a professional to go for the right kind of support so that the weight-bearing capacity will be optimum. You can use trusses to stabilize the building.

The walls are supported in a very efficient manner. If there are more than two stories, the roof truss can be constructed very efficiently so that the load distribution will be done very efficiently. You can go for a cost-effective solution with a roof truss.

As roof trusses are triangular in shape, they can be installed very easily. Various kinds of materials are used in the construction of a roof truss.

A small garage can be constructed by following the tips and hints offered by experts. If you use timber as the material, you can secure panels together after cutting the timber. The brace should be added before secure trusses, and the roof trusses should be attached.

You should verify the local and building code before starting the construction. Safety precautions should be taken to prevent accidents at the time of construction, and the storage space can be used very efficiently for a long period of time. The Periodic inspection should be done to assess the strength and stability of the structure.

FACTORS OF CONCERN

If you are going for a roof truss to construct a house by a Civil Building contractor or shed or garage, it should not be based on the aesthetics alone. You are advised to approach an experienced truss designer so that stress, strain, tension, and weight-bearing capacity will be assessed systematically. The technical aspects should be addressed by competent personnel not to take a risk with the construction.

An experienced engineer or architect will help in the construction of various kinds of structures with roof trusses. In a single house or garage, you might want to go for various roof trusses as per the functionality. The rooms or available space can be customized as per your needs by making changes in the design. However, you can manage the same exterior looks.

One can build warehouses, cold storage, garages, and sheds using truss work. It is possible to construct your own roof trusses as well. The professional architect should prepare a design layout. The layout can be prepared in the system by using the software as well. There are specialized software applications that are meant to design roof trusses.

You should choose the right kind of materials and connector plates. A roof truss can be prepared with other materials such as steel, aluminium, or tin. The material should be cut as per the size of the roof and specifications. The strength of the base of the roofing should be calculated while building roof trusses.

Different Types of Truss Work designs used in Truss Fabrications?

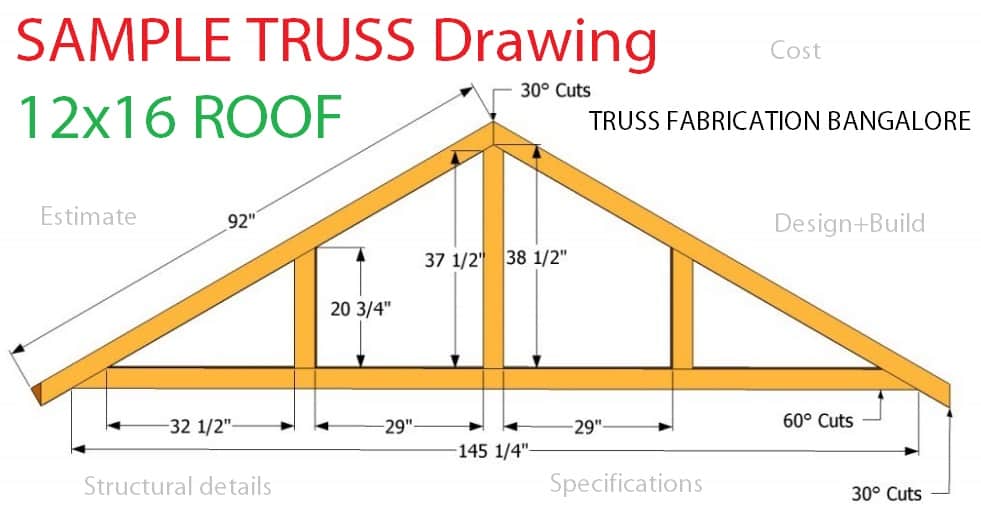

Various types of roof trusses are used as per the span. Some examples of roof trusses are king post, queen post, fink, double ‘we, small cantilever, large single cantilever, large double cantilever, asymmetric, mono-pitch, room in the roof, open jack, bobtail, and double bobtail (stub).

Trusses are prepared from wood, steel, aluminium, and tin as per the design specifications and applications. The load-bearing capacity should be optimum, and the load should be distributed in a very efficient manner with the help of truss work.

As trusses are solid and cost-effective, there is great demand for truss structures. There are various kinds of truss designs that are meant to optimize the material cost or labour cost, or both. You should choose the right kind of truss work that will be benefited from the design.

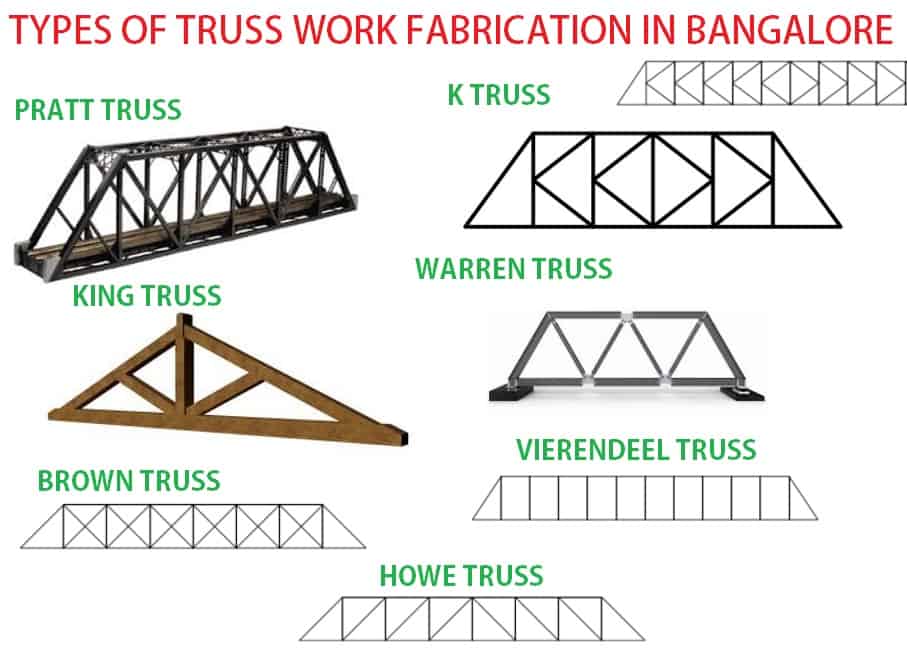

PRATT TRUSS

Pratt Truss is one of the effective trusses, and it is being used for the last two centuries. In this truss work, the vertical members undergo compression while the inclined members are subjected to tension.

The requirement for steel can be reduced as the tension will be borne by other kinds of materials positioned in diagonal locations. You can go for steel with low density as well so that there will be great savings through the entire design.

If you are going for horizontal spans, you can go for Pratt Truss without any issues. When you go for a Pratt truss, you are aware of the subjective force of members.

It is possible to design a cost-effective structure. The design is straightforward, and it is well accepted in the industry. The greatest drawback is that that it may fail to withstand the weight subjected to other angles.

You can opt for truss work if you are on a budget. You should opt for the structure as it is very simple, and a mix of loads can be applied.

K TRUSS

K Truss is complicated than the Pratt Truss. The vertical members will be shortened in K Truss. It is done to improve the buckling resistance. Even though the K Truss is not very popular, it offers great stability. However, the reliability of members is not optimum. It is the greatest drawback of the Truss. The member will be subjected to compression as well as tension in various scenarios.

The advantage of the K Truss is the reduction in compression on members. It is possible to reduce the cost of the structure as the requirement of steel quantity will below. The drawbacks of the K Truss are complicated design.

WARREN TRUSS

Warren truss is made up of equilateral triangles. The load distribution will take place across several members so that the structural stability is very much enhanced. If you are building a structure where the distribution of load occurs, you will benefit from the Warren Truss. There will be concentrated force under a point load.

The structure fails to distribute the load in a very efficient manner when the load is concentrated. Thus, you can apply Warren Truss for spanned loads so that there will not be any issues. Half of the members will be subjected to compression loads, and the rest will be subjected to tension loads.

The advantage with Warren Truss is that the load will be spread evenly among members. It is a very simple design. The drawback of the Warren Truss is the poor performance under concentrated loads. The constructability will increase as additional members are attached to the design. The Warren Truss can be applied to load span structures. The evenly distributed load will be supported in a very efficient manner. You can manage simple structures as well with the help of Warren Truss.

OTHER TYPES OF TRUSSES

If you chose a wooden truss, King Truss is ideal. In some cases, it can be built by using steel and wood as well. Spans up to 8 meters can be managed efficiently with the help of King Truss.

• Queen post truss is meant for wooden structures. The span length can be up to 10 meters when you go for a queen post truss.

• A combination of wood and steel is used for the preparation of Howe Truss. The vertical members (tension) members are made of steel. You can apply the Howe truss for span length in between 6 and 30 meters.

• A Fan Truss is made of steel. You can understand a Fan truss as a form of Fink roof truss. The top chords will be divided into small lengths, and they will provide support for purlins. You can manage the span length in between 10 and 15 meters.

• The North Light Roof Truss can be used if the span length is more than 15 meters. This kind of roof truss is very much economical. Wide-span lattice girders can be arranged so that there will be great support for trusses at 90 degrees. You should take additional measures to light up space.

The lighting should be provided on the top of the roof and sides so that there will be sufficient illumination. The greatest advantage with North Light Roof Truss is that you will be able to cover large areas in a very efficient manner. The span length will be between 20 and 30 meters. The roof truss can be used for industrial sheds and drawing rooms.

• Railway sheds and auditoriums can be constructed by implementing the Quadrangular roof Trusses. The truss can be considered as two trussed rafters. The two trusses will be held in place with a tie, T at the centre.

Some members are subjected to compression, and others are subjected to tension. The members should be designed to withstand the maximum load. The stress that occurs due to wind and snow should be assessed, and it should be incorporated into the design.