Contents

Different Construction Materials required for Building your House

One requires various construction materials in Bangalore or Building materials in Bangalore for building a new House. These materials should be procured as per the size of the construction. Construction materials should be well-integrated so that you will derive maximum benefit without any issues.

One should know where you get building materials from and how to manage them properly. It is also essential to take the guidance of architects appointed to work on your project if you have read through the details mentioned below.

One can save a lot of time and money. The construction can take place in a hassle-free environment once you understand these materials and where they are used in building your dream home.

Construction method

Materials required for construction will be mentioned in the designing stage when professionally planned by an Architect who provides detailed BOQ’s for house construction.

Structural materials required for construction are based upon the type of construction method applied. The material requirement might change during the construction stage. Proper house planning should be done so that you will procure materials from the right location and at the right time.

Ready-mix concrete is very much required for foundation, irrespective of the type of construction that takes place. If you go for insulated concrete forms, you will need a large quantity of concrete and a pump.

The majority of building supplies from walling to roofing can be procured from the local merchant. If you go to the ‘off-site’ construction method, most of the materials will be supplied by a specialist manufacturer.

Different Building materials in Bangalore required for Construction

|

Sl no |

DESCRIPTION Of Construction materials in Bangalore or Building |

Construction material RATES (IN RS.) |

|

REMARKS |

||

|

|

|

|

|

|

|

|

|

|

|

PIECE |

CFT |

TON |

LOAD |

|

|

|

|

|

|

|

|

|

|

1 |

M SAND cost |

|

|

800 |

|

+GST 5% |

|

|

|

|

|

|

|

|

|

2 |

M SAND |

|

|

950 |

|

+GST 5% |

|

|

CONCRETE(WASHED) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

M SAND |

|

|

1350 |

|

+GST 5% |

|

|

PLASTERING(WASHED) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

RIVER SAND |

|

|

2500 |

|

+GST 5% |

|

|

|

|

|

|

|

|

|

5 |

TABLE MOULD BRICKS |

6.25 |

|

|

|

+GST 5% |

|

|

|

|

|

|

|

|

|

6 |

WIRE CUT BRICKS |

8.25 |

|

|

|

+GST 5% |

|

|

|

|

|

|

|

|

|

7 |

JELLY (AGGREGATES) |

|

|

|

|

+GST 5% |

|

|

|

|

|

|

|

|

|

|

12mm |

|

|

750 |

|

|

|

|

|

|

|

|

|

|

|

|

20mm |

|

|

750 |

|

|

|

|

|

|

|

|

|

|

|

|

40mm |

|

|

750 |

|

|

|

|

|

|

|

|

|

|

|

8 |

LIGHTWEIGHT AAC |

|

|

|

|

|

|

|

BLOCKS |

|

|

|

|

GST IS |

|

|

|

|

|

|

|

INCLUDED IN |

|

|

4 INCH |

45 |

|

|

|

|

|

|

|

|

|

THE |

||

|

|

|

|

|

|

|

|

|

|

6 INCH |

65 |

|

|

|

MENTIONED |

|

|

|

|

|

|

|

COST |

|

|

8 INCH |

89 |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

9 |

SOLID BLOCKS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 INCH |

26 |

|

|

|

|

|

|

6 INCH |

32 |

|

|

|

+GST 18% |

|

|

|

|

|

|

|

|

|

|

8 INCH |

44 |

|

|

|

|

|

|

|

|

|

|

|

|

xx

|

Sl no |

DESCRIPTION Steel TMT bars |

|

RATES (IN Rs) |

|

REMARKS |

||

|

|

|

|

|

|

|

|

|

|

|

|

PIECE |

|

CFT |

TON |

LOAD |

|

|

1 |

STEEL TMT BARS |

|

|

|

|

|

|

|

|

VRKP Steel |

|

|

|

49,000 |

|

|

|

|

|

|

|

|

|

|

GST |

|

|

INDUS Steel |

|

|

|

56,500 |

|

|

|

|

|

|

|

|

INCLUDED IN |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

THE |

|

|

RD Steel |

|

|

|

49,500 |

|

|

|

|

|

|

|

|

MENTIONED |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COST |

|

|

KAMADHENU Steel |

|

|

|

53,000 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MEENAKSHI Steel |

|

|

|

51,000 |

|

|

|

|

|

|

|

|

|

|

|

|

2 |

CEMENT/50 KG |

|

|

|

|

|

|

|

|

BAG |

|

|

|

|

|

|

|

|

(MIN 100 BAG) |

|

|

|

|

|

|

|

|

BIRLA SUPER |

340 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ACC Cement |

335 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PENNA Cement |

290 |

|

|

|

|

GST |

|

|

|

|

|

|

|

|

|

|

|

RAMCO Cement |

315 |

|

|

|

|

INCLUDED |

|

|

|

|

|

|

|

|

IN THE |

|

|

BHARATHI Cement |

315 |

|

|

|

|

|

|

|

|

|

|

|

MENTIONED |

||

|

|

|

|

|

|

|

|

|

|

|

ULTRATECH Cement |

335 |

|

|

|

|

|

|

|

|

|

|

|

COST |

||

|

|

|

|

|

|

|

|

|

|

|

ZUARI Cement |

320 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CHETTINADU Cement |

290 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COROMANDEL Cement |

305 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PRIYA GOLD Cement |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BIRLA SHAKTHI Cement |

310 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NAGARJUNA Cement |

275 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DALMIYA Cement |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MAHA Cement |

290 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

—

Various kinds of natural as well as man-made Building materials are used in the house construction process. Natural materials include rocks, sand, clay, m sand, plaster sand and wood. These building materials required for the construction process is categorized as per the trade, such as carpentry, plumbing, civil works, plastering and roofing.

The quality of soil will play an important role in the construction process. Larger amounts of clay will be used in the adobe-style building, and lower amounts of soil are used in sod building. Sand and gravel are other important materials that are used in the construction process.

To create walls, rammed earth will be used. To increase the strength of walls, forms and pneumatic compressors are used in building construction.

Rock is a very dense material, and it offers great protection. The only drawback associated with rocks is that they are cumbersome and don’t deliver an impressive look.

Stone buildings and stone walls were built from time immemorial—some civilizations built constructions based on stone only. The Egyptian pyramids are the best example in this context.

CEMENT

Cement is nothing but a binder. It will harden itself or bind together with other materials. There are types of cement that harden continuously because of

Portland cement will harden because of hydration and chemical reactions that take place because of the presence of moisture. To retain strength, non-hydraulic cement such as lime and gypsum plaster is used.

They should be kept dry so that they will retain strength without any issue. Portland cement is available in different grades. The selection of the cement should be made based on its compression strength. High-grade cement is used in the construction of residential as well as commercial buildings.

CHEMICAL Composition of CEMENT

60% to 70% – LIME (CaO)

20% to 25% – SILICA (SiO2)

5% to 10% – ALUMINIA (Al2O3)

2% to 3% – FERRIC OXIDE (Fe2O3)

What is 43 Grade CEMENT?

Ordinary Portland cement (OPC) is available in grades such as 33, 43, and 53. The compression strength of cement concrete after 28 days of setting will be measured to certify the cement grade.

If you go for 43 grade cement, you will get a compression strength of 43 mpa (megapascals) in 28 days. 43 grade cement is used in general civil engineering construction work. Plastering, painting, flooring, brick masonry, and RCC work will be done very efficiently with 43-grade cement. The design strength of 43 grade cement will be of the order of 430 kg/sq cm.

The drawback with 43 grade cement is that it will attain strength slowly. However, it will attain the same strength that is attained with 53 grade cement after some time. The hydration process in 43 grade cement will be slow. The heat release will be very less. Proper care should be taken to avoid micro-cracking. Ordinary and small-scale consumers can go for 33 grade of cement also as per their needs.

If you need to know the current details, you can visit these specific links of 30×40 construction cost, and regarding planning, you can visit the links of 30×40 House plans 40×60 house plans or Duplex house plans.

What is 53 Grade CEMENT?

If you go for 53-grade cement, you will get a compression strength of 53 mpa (megapascals) in 28 days. 53 grade cement is available in an ordinary mode as well as in special mode. If the initial strength is to be achieved very quickly, it must go for 53 grade cement. The construction pace will be very fast with 53 grade cement.

It is used for a fast setting. The strength attained in 7 days will be 27 mpa with 53 grade, whereas the strength attained with 43 grade will be just 23 mpa in 7 days. The initial higher strength is the criteria with 53 grade OPC, and it is commonly used for plastering works. It is used in RCC and pre-stressed concrete of higher grades. The cost of 53 grade cement is higher than 43 grade cement, and it will be of the order of 2% to 3%.

STEEL / TMT BARS

The structural framework of high-rise buildings is done by metal. It is used as an external surface covering element. Steel is the most common element used in structural building materials.

It is very strong and can be treated to deliver long-lasting results. As corrosion is the main enemy of steel, alternative materials are used for other purposes.

Aluminum alloys are light in weight, and they offer better corrosion resistance properties. Many pre-fabricated structures are used for this purpose. Expensive materials are used for specific purposes. They enhance the beauty of your home in a very efficient way.

How are TMT Bars Manufactured..?

When work hardening and heat-treatment are integrated into a single process, it is called a thermo-mechanical process. If bars are treated in this process, they are called TMT bars. The applications of TMT bars include rebar steel.

The process is intended to enhance the strength of low-carbon steel inexpensively. The surface layer of the bar will be quenched. In this process, the crystal structure’s deformation will take place, and intermediate layers will be pressurized. At the same time, quenched layers will be tempered using the heat available from the core.

TMT bars’ outer surface will be very hard, and the inner core will be very soft. As part of the manufacturing process, hot rolled steel wires will go through the water as well. The weld-ability of the product improves, and corrosion resistance will also improve in this process.

As the metal’s outer surface will be cooled at a much faster pace than the core of the metal, there will be a great temperature gradient from the bar axis to the periphery. The residual stress in TMT bars will be lesser than HYSD (High Yield Strength Deformed) Bars. The corrosion resistance is also very high. The ductility of TMT bars is higher than the similar strength grade of bars.

Difference Between TMT Bars and Twisted Bars..?

There is a difference between twisted bars and TMT bars. Twisted bars refer to cold treated bars, and TMT bars refer to hot treated bars. TMT bars will go through three stages of processing. They are quenching self-tempering and atmospheric cooling.

As there will not be any twisting during the TMT process, no torsional stress takes place. Hence, there will not be any surface defects in TMT bars. TMT bars have a martensite microstructure. Hence, the tensile strength will be higher than the twisted bars.

Superior bend properties, better elongation, fire resistance, high fatigue resistance, and good weldability & formability are some of the factors which make it an ideal choice in the construction industry. Hence, TMT products are used to construct bridges, dams, structures, high-rise buildings, concrete reinforcement, and underground platforms.

BRICKS

There are various kinds of bricks in the market. They are used as per the application. Bricks available in the market are categorized under various headings. There are unburnt (sun-dried) bricks and burnt bricks. If the construction is done temporarily, you can go for unburnt bricks. If the structure is exposed to heavy rains, it will be damaged.

Different Types of Bricks.?

The brick mold will be burnt inside the factory, and these are very commonly used in construction. They are classified into four types: first

These shapes include bullnose brick, channel brick, coping brick, cownose brick, curved sector bricks, hollow bricks, paving bricks, perforated bricks, and purpose-made bricks. Bricks used by masonry are also categorized as common burnt clay bricks, sand-lime bricks, engineering bricks, concrete bricks, and fly ash clay bricks.

How BRICKS are Manufactured..?

Bricks manufactured at extremely high temperatures are termed engineering bricks. A very dense and strong brick will be formed so that the strength is very much enhanced and water absorption will be limited. In addition to damp-proof characteristics, there will be an excellent load-bearing capacity with engineering bricks.

You will get protection from heat and cold by installing highly efficient bricks at home. Natural bricks are made in various colors. It is possible to achieve various textures in a very efficient way.

You can take advantage of the excellent compression strength offered by bricks. Bricks should have the capability to release as well as absorb moisture in a very efficient way. The humidity, as well as temperature, should be well-regulated.

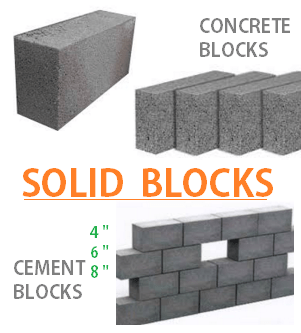

CONCRETE SOLID BLOCKS

Concrete bricks are made from solid concrete. They are placed in facades and fences. There will be great strength enhancement with solid

You can go for energy-saving and environment-friendly solid concrete blocks. The water absorption will be lowered, and high strength will be achieved. There will be better sound insulation, consistency, precision & accuracy associated with solid concrete blocks.

How are Solid Concrete Blocks manufactured..?

The concrete block is made up of Portland cement, blended cement, water, and various aggregates. These units are also referred to as concrete masonry units (CMU).

They are very inexpensive, durable, and lightweight. The installation can be done very easily. The fireproof, low maintenance and ornamental value of the block are used in various construction applications. You can obtain decorative finishing by going for solid concrete blocks.

Sizes of Concrete Solid Blocks – 4” 6 “ 8”

The end of the block might be flat or flanged. The compressible strength and fire resistance offered by the block is based on the block’s configuration. Pumice is the natural aggregate. Other materials are cinders and slag.

Some concrete blocks’ historical uses include foundation walls, basement walls, partition walls, and exterior walls. Concrete blocks are used as backup material or for cavity wall construction. By applying coatings, water penetration through blocks will be prevented. Oil and rubber-based coatings, latex paints, and Portland cement paints are used in this process.

RIVER SAND

You should choose the right kind of sand for construction. River sand is procured from river beds. It is fine sand which is different from pit

It is used in the construction process. There are many applications of river sand. As the sand will be very clean, it will be white in color. It is a naturally occurring material that is produced from finely divided rocks and mineral particles.

The size of the sand is finer than gravel, and it is coarser than silt.

The soil is also called a textured class of soil. It contains more than 85% of sand-sized particles.

The sand can be used for various purposes.

The composition varies based on rock sources and conditions. Silica is the most common constituent in the sand. It is available in the form of quartz.

Calcium carbonate is the second most common type of sand. It is created by various forms of life, such as corals and shellfish. You can find this kind of sand in reefs.

Why we use River Sand for Construction..?

The diameter of a sand particle will be in the range between 0.0625 mm and 2 mm. The individual particle diameter will be as small as 0.02 mm. you can go for unwashed river sand and washed river sand as per your needs. Unwashed river sand will be mined from old river banks.

The sand will be coarser than other kinds of sand. River sand consists of small pebbles of about 2 to 3 mm. The presence of small pebbles attributes the strength and binding qualities.

The floor can be topped up very efficiently by adding sand to the cement. After the mortar sets in, you will realize the hardness of the composite. If you go for good quality washed river sand, plastering, building, and topping can be done very efficiently.

The specialist sand is expensive, and it works like a filter as well. If vegetation and organics are screened, it is termed dune sand. When lime is added to the sand, the quality of sand will improve. The high-quality finish can be obtained by using premix plaster sand.

M SAND / MANUFACTURED SAND / ROBO SAND

Manufactured sand (M SAND) is used as a substitute for river sand. This kind of sand is produced from granite stone. The granite will be crushed,

The cost of construction can be decreased by going for manufactured sand. As there is great growth in the construction industry, the demand for natural has increased.

Due to the non-availability of natural sand from a local area, manufactured sand took place.

With this invention, transportation cost has decreased tremendously. The advantage of M-sand is that it is dust-free. You can exercise control on the size of the M-sand as per the grading of the construction. There are many advantages associated with M-sand.

The well-graded sand can be used in the required proportion as per your needs. no organic or soluble compound is present in M-sand. Hence, the setting will take place very quickly. It is possible to manage the required strength very easily.

Advantages of M Sand over Natural River Sand

Impurities such as clay, silt, and dust are eliminated in a very efficient way. The bond between cement paste and aggregate will be perfect. The durability of concrete is very much enhanced by using M-Sand.

By using state-of-the-art technology, manufactured sand is produced from granite. You will obtain the property required by the sand so that high-quality construction will take place. The sand is manufactured by following the technology, similar to the mechanism undergone by natural sand.

How M Sand in Manufactured..?

By using modern machines, high-quality sand will be produced. Fine crushing and separation technology is used to produce a very high-quality product. It is possible to produce sand as per local regulations. The consistency of the product can be maintained across various batches. There will be a control on the mix and the strength that is attained with the aggregate.

Fine and coarse particles are separated by air classification technology. Specifications are met, and very high-quality products are produced by exercising control over the production of manufactured sand.

DOORS

Various kinds of doors are used in house construction. The most common types of doors include wood, steel, fibreglass. The size of the door is

Where doors can be Designed ..?

The indoor doors should have noise-reducing characteristics. If you go for a solid door, there will be great noise reduction and protection as well. It is less expensive. However, the door is prone to scratches and dents. The type and size of the doorway opening should be considered while purchasing doors.

There are solid wood doors as well as wood veneer doors. Wood veneer doors come with solid wood fibre or hollow portion. As the solid wood-based door is made from a single piece, it is very heavy. Hollow doors can be installed for interiors. Closets and bedrooms can be managed by installing hollow doors.

Maintenance involved..?

Steel doors are inexpensive. The maintenance cost is also very low. Steel doors provide great security. You can go for 22 gauge metal doors which lasts longer than 24 gauge metal doors. The 22 gauge will not chip or bend, so that you can use it for many years.

If you want to install affordable doors, you can consider fibreglass doors. They are secure, durable, and can be maintained very easily. Some doors are prepared with wooden grain. They will withstand moisture and humidity in a very efficient way.

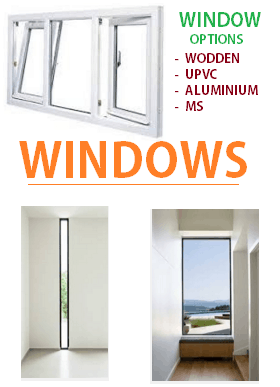

WINDOWS

There are windows of various sizes and styles. You can notice a difference in terms of structure and mechanism. Side-hinged windows are also

Different Window Options available..?

– Wooden.

– UPVC.

– Aluminum.

– MS Steel.

You can go for custom-built windows. The manufacturer’s instructions should be followed very carefully so that you will use them as per your needs very efficiently. Your windows will define the style of your house.

The natural light will be allowed by windows so that there will be less dependence upon electrical lights. You will also need to allow fresh air and sunlight to keep rooms and walls dry.

In the case of double-hung windows, there will be two sashes that slide vertically up and down in the frame. You can open them from the top or bottom very easily. If you go for single-hung windows, the bottom part of the windows will be operational, and the top part will be stationary.

Casement windows operate by the turn of a crank.

There will be hinges on the left or right side, and windows will be opened outward. Awning windows will have hinges on the top. They will open outward so that the air will enter from left, right, or bottom. You can install it along with a stationary or operating window.

The maximum amount of light flows through the picture window, and you will enjoy excellent outdoors. The transom window is a small window that is mounted above a door or window. The window is used to let the air and light. Slider windows glide along the tracks. One operating window will move against the other window. They are used in modern as well as contemporary-style houses.

SANITARY WARE / BATH WARE FITTINGS

To design a perfect bathroom, you should go for the right kind of bath ware fittings. You should go for high-quality bath and shower fittings so that

The selection of faucets, bathroom mirrors and bath accessories should be made as per your needs.

A wide range of showers, faucets, stop cocks, floor drains, and mixers are available in the market. Basin taps, washbasins, bath taps, mixers, taps’ accessories, and floor drains can be selected as per the budget, color, size and shape.

You can turn your old bathroom into a modern bathroom suite as part of a renovation. The selection of various fittings should be made carefully to address aesthetics and functionality very easily.

A typical bathroom suite comprises of washbasin, toilet, bath, vanity cabinets, and mirrors. In addition to the bath, you can add a shower enclosure. If you would like to double the bathroom’s purpose, you can install a bidet as well.

A perfect bathroom that reflects your lifestyle and taste can be managed very easily by taking an interior designer’s help.

The material of bathroom fittings can be made up of steel or acrylic. If there is difficulty in entering and exiting the bath, a bath’s walk-in style can be selected. You can choose a wall hung, corner basin, counter-top and vanity basin as per your needs. The size of the fitting and placement of fitting should be considered very carefully so that you will settle for the best bath ware fittings.

FLOORING

The appearance and finishing of a project are dependent upon the type of flooring. If you manage good looking flooring, the value of the property

Hardwood flooring is made up of various kinds of wood types, including Beech, Pecan, Maple, Cherry, Oak, Pine, Walnut, and Hickory. You can produce a long-lasting and wear-resistant finish by going for hardwood flooring. The drawbacks associated with some kinds of hardwood flooring include darkening with age and shrinkage.

You can go for bamboo flooring if you would like to go for green flooring solutions. It is durable and available in various colors. Highly elegant flooring solutions are offered through bamboo flooring.

Even though you can manage a very strong and clean surface, the surface might darken over a period of time. There will be a change with exposure to sunlight as well.

The flooring should not be exposed to dampness as well.

If you would like to go for a waterproof flooring solution, you can choose ceramic tile. You can use ceramic tiles for indoor applications, such as countertops and floor tiles. If there is an unglazed finish, they can be used for outdoor flooring very efficiently. Various kinds of finishes can be obtained, such as matte, glazed, embossed, and texture.

You can manage laminate flooring very easily. A strong and durable surface can be attained, and it is possible to prevent scratches, burns and chipping very efficiently.

WALL CLADDING

Wall cladding is done to enhance the appearance of the building. It has a protective element as well. One layer is formed by applying one

The run-off will be controlled, and the control element will direct water or wind quickly. The noise from entering the wall will be prevented. If the cladding is done to windows, it is called window capping.

The non-load bearing skin or layer is added to the exteriors of your house. The water will be shed in this process. The building will be protected from elements of weather. The special treatment given to walls very much influence the building cost and aesthetics.

They are durable and aesthetically-pleasing appearance will be produced by going for wall cladding.

However, it should be maintained so that the life span of the building will be enhanced. The choice of cladding should be exercised based on the orientation of your home. You should choose cladding materials that are specific to elevation or exposure.

Durable steel is used to deal with west-facing gable walls. Weatherboard is used to get sun-protected north, south, and courtyard walls.

The most common type of materials used for cladding is wood, metal, and plastic. An increasing range of composite materials is also used in this context. Cladding options should be exercised in terms of colour, texture, environmental impacts, embodied energy, structural capability, insulation, and thermal mass.

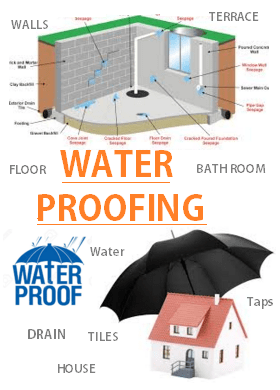

WATER PROOFING

Waterproofing should be done properly so that the structure will be protected and the life of the building will be very much enhanced. The concrete

To overcome the drawbacks associated with concrete, precautionary steps should be taken. There are conventional as well as non-conventional methods that are used in this process.

By giving cement-lime based treatments and bituminous coatings, waterproofing will be done in a very efficient way. By using modern materials, it is possible to produce a damp-proof structure.

The moisture migration through capillary reaction will be reduced by using water-repelling materials. There are positive as well as negative waterproofing solutions. In the case of positive waterproofing, it will be applied on the same side of the applied hydrostatic pressure. Negative side waterproofing will be done on the other side of the applied hydrostatic pressure.

Some of the waterproofing methods are the brickbat Coba method, cement/lime based treatments, elastomeric membrane forming methods, silicon-based impregnators (as water repellents) bituminous based products.

Modified bitumen and bituminous products are very economical. They are flexible and have a crack-bridging capacity.

Coating the surface with cement lime mortar is one of the oldest practices. However, the load of the structure will be increased in this process, and it is not flexible. The breathing capacity of the concrete is retained with mineral slurry with polymer cement.

Epoxy & polyurethane coating gives great abrasion resistance, and it is resistant to UV rays as well. However, you should compromise on the breathing capacity of concrete.

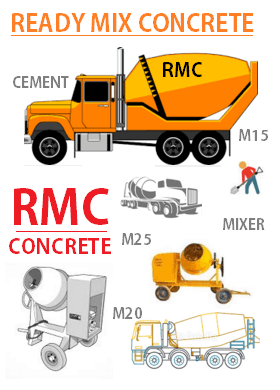

Ready Mix Concrete – RMC

Ready-mix concrete (RMC) contains cement, water, aggregate, and other elements. The centrally located plant will process the mixture, and the

What is Concrete..?

It is a composite material made up of different elements. The aggregate will be combined with a binder such as cement to produce a very strong substance. Gravel, sand, water, and Portland cement are the most important constituents of concrete. The cement hydrates, and the entire mixture will become like a stone.

The tensile strength of concrete is very low. Hence, it is enhanced by using steel rods or bars. The concrete which is strengthened in this form is called reinforced concrete. Concrete is a long-lasting material. The concrete forming and construction steps will be combined through the recent advancements, insulating concrete forms.

For concrete formation, the ratio of cement, sand, and gravel should be 1 : 2 : 3. Different ratios are used for wall construction, plastering. The mixture should be used within 3 to 4 hours to get the best results.

What are the Different Grades of Concrete?

There are different grades of concrete in the market. The selection should be made based on your requirements, such as strength and cost. The grade selection is based on applications such as beams, slabs, columns, and foundations. To beat out the drawbacks associated with the weak soil, the building’s weight should be assessed properly.

Low-density concrete:

The density of traditional concrete is of the order of 2200 to 2600. The self-weight of lightweight concrete is between 300 and 1850 kg/m3. The dead load will be reduced drastically, and the progress of the building will be increased.

Hauling and handling costs will be reduced. If you go for frame structure, the beam and column should carry a load of the wall and floor very efficiently. The thermal conductivity of lightweight concrete is very low.

High-density concrete:

The strength of high-density concrete varies from 3360 kg/m3 to 3840 kg/m3. If iron is used as fine and coarse aggregate, the density will be 5820 kg/m3. Heavy natural aggregates are used in heavyweight concrete.

These natural aggregates include barites and magnetite. If barites are used, the density will be around 3,500 kg/m3. It is possible to use manufactured aggregates as well, such as iron or lead shot.

The type of aggregate influences the density. The density of high-density concrete is 45% greater than the normal concrete. It is possible to achieve very heavy strength by going for iron or lead shot, and it will be in the range between 5,900 kg/m3 and 8,900 kg/m3.

The typical applications include the construction of radiation shields and the ballasting of pipelines.

Mass concrete:

Strength is the secondary concern when you go for mass concrete. The design will be based on durability, thermal action, and economy. The thermal behaviour is the most distinguishing factor of mass concrete from other types of concrete.

Sufficient measures should be taken while dealing with cracks that arise with thermal behaviour. The structural integrity should be protected, and seepage should be contained.

STONE AGGREGATES / GRANITE JELLYSTONE

Aggregates are mined materials. There are different kinds of stone aggregates in Bangalore. These include granite aggregates, jelly stones, gravel

The hard rock of the granular structure will be crushed to prepare granite aggregate. Granite rock is prepared from the magma which is generated on the ground surface. It is one of the most popular building materials.

There are different grades of granite. They are solid, highly solid, and frost resistant. The flakiness index of granite is very low. It is between 5% and 23%. Granite does not contain radionuclide content, additive indicators, and harmful components. Even if they are present, they are within the permissible limit.

Why we use Granite Aggregates for Construction..?

Granite aggregates are used in construction for various purposes. The smallest granite aggregate (0 to 2 mm and 0 to 5 mm) are used in road construction, pavements, and covering sports grounds. These aggregates are also used in RCC structures.

Granite sand is used in landscape architecture. A 2 to 5 mm granite aggregate is used in paving slab and other construction projects. 3 to 10 mm aggregate is used in road construction and the production of concrete.

Gravel aggregate is obtained by crushing natural stone rock and sifting quarried rock. Gravel aggregate is inferior to granite aggregate. They are cheaper than granite aggregate, and the radioactive background of the material is usually low. Gravel aggregate is used in the construction of foundation and concrete. It is used in road construction as well.

Types for Aggregates used.?

Two types of gravel aggregates are available in the market. They are scabbed stone and gravel. Gravel aggregates are available in various sizes, including 3 to 10 mm, 5 to 20 mm, 5 to 40 mm, and 20 to 40 mm.

Limestone aggregates are derived through the crushing of the sedimentary rock limestone. It is mainly composed of calcite (CaCO3). Limestone aggregate is also called dolomite aggregate. It is used in the construction and the production of reinforced concrete objects.

There are secondary aggregates as well, which are procured by crushing the construction waste.

The material used for this purpose includes concrete, bricks, and asphalt. It is 2 times cheaper than the granite aggregate. You will need 8 times lower power for the production of secondary aggregate. However, you should compromise on frost resistance, strength, and other parameters compared to granite aggregate.

The aggregate is used as a filler in large-scale construction practices. It is used in road construction, maintenance works and reinforcing weak soils.

GLASS

Small openings of buildings are covered with glass. You can use glass for windows to let the light enter the room, and there will be a protective element. Glass is used in architectural buildings. Glass curtain walls will cover the entire façade of the building.

PLASTIC

Plastic pipes are used in construction for various purposes. They are used to supply water and sewage purposes as well. The modern plastic material is heat tolerant. Pipes are tough, and resilience is also very high.

As they are light in weight, they can be used for various purposes very easily. Plastic pipes are inserted inside walls and concrete structure as well so that electrical wiring can be done very easily.

Building materials are made from various ready-made materials. Architectural hardware, as well as decorative hardware, is used for various purposes. Support for fixtures like windows, doors, and cabinets will be provided very efficiently using various kinds of materials. Various miscellaneous items such as glues, caulking, and paint are also used in this process.

Using very high-quality products makes it possible to improve the quality of construction, and the structure will last for many years without any issues. If you purchase from a reputed local merchant, there will be continuity of supply at the best price.

What are the different Construction materials in Bangalore required for house construction?

The different construction materials required for building a House which includes Cement, River Sand, M Sand, Bricks, Blocks, TMT Bars Steel, Jelly / Stone aggregates, Granite, Marble, etc.

What is the Cost/Price list of Building materials/Construction materials in Bangalore?

The Price/cost of construction materials or building materials are Cement : Rs 350 to 410 per bag |TMT Steel BARs : Rs 44,000 to 60,000 per ton | M Sand : Rs 600 to 999 per ton | Stone aggregates/Jelly: Rs 520 to 600 per ton | RMC : Rs 4500 to 5200 / Mcube.

What are the different Cement grades in Bangalore for building a House?

There are different cement grades that can be used in construction like M 33 Grade | M 43 Grade | M 53 Grade. Each cement grade has its own properties and usage.

What are the different Ready Mix Concrete RMC grades available in Bangalore and its cost?

There are different RMC Ready Mix Concrete grades like M20 Grade | M25 Grade | M30 Grade | M35 Grade.

What is the different Building/Construction materials used in construction of a Wall during house construction?

The different construction materials or building materials that can be used for wall construction are Red Bricks | Solid Cement Bricks | Fly Ash Bricks | Wire cut Bricks | Holly Bricks/Blocks, etc.

What are different Construction or Building materials that can be used in Flooring for a House?

There are different construction of building materials that can be used for Flooring such as Granite | Marble | Vitrified Tilts | Wooden Flooring | Sand Stone | Clay Tiles, etc.

What is the cost of TMT Steel Bars in Bangalore?

The cost of TMT Steel Bars varies from Rs 44,000 to Rs 58,000 / per ton it depends on the BRAND and composition of the TMT Bar such as Fe-500 TMT | Fe-500 D TMT Bars | Fe-550 TMT | Fe-550 D TMT Bars | Fe-600 TMT Bars.

What is the Price/Cost of Cement in Bangalore per bag?

The Price of Cement or cost of Cement per bag varies from Rs 350 / bag it also depends on the BRAND and type such as 43 Grade Cement | 53 Grade Cement | Portland Pozzolana PPC Cement | Portland Slag Cement PSC Cement.

What is the cost of or price of Ready Mix Concrete RMC in Bangalore?

The Cost of RMC or the Price of RMC varies from Rs 4500 to Rs 5200 /Mcube depending on the grade of Ready Mix Concrete RMC like M20 | M25 | M30.

What M Sand rates in Bangalore? Different Types of M Sand used in House construction?

M Sand rates start from Rs 500 to Rs 999 /ton. Types of M Sand that can be used for house construction like Single wash M Sand | Double wash M Sand | Double wash Plastering M Sand.

highly informative